The primary use is chemical mixing as well as the variants are definitely the pressure, temperature, gases used (hydrogenation / chlorination) and catalysts. Glass lined reactors have the ability to be cleaned to your higher conventional which helps prevent batch have more than.

This is actually the null position — a temperature at which the glass is under neither compression nor stress. In the event the glass lining cools to ambient temperature, it really is less than a residual compressive pressure, which enormously strengthens the glass and makes it proof against thermal and mechanical shock. However, too much compression in glass improves the tendency of convex glass surfaces, for instance exterior radii or vessel nozzles, to spall.

In past week’s web site put up, we talked about some very best procedures for running and retaining your glass-lined devices, together with what behaviors to avoid (get on top of things and skim "aspect one" when you haven't presently).

Quite a few applications: The Enamel’s chemical resistance presents extremely violent media for the appliance.

This example illustrates that the heat transfer benefits of the 50 percent-coil jacketed vessel in stable steel reactors are usually not relevant to glass-lined vessels, mainly because essentially it's the glass layer that decides the heat transfer rate. The selection to employ a 50 percent-coil jacketed vessel is for that reason dependent on other criteria, for example, when pretty superior expected pressure is needed on the heating/cooling aspect or when it is necessary to different the sections on the half-coil jacket with incompatible heating/cooling brokers (two-way half-coil jacket). The double-jacketed vessel, usually, is the more affordable and durable development alternative, Particularly due to the usage of agitating nozzles for warmth transfer fluid provide.

All Pfaudler tools is recorded in the databases of drawings and design options, obtainable for their entire lifecycle. In this manner, we are able to warranty to supply capable technological aid, even for more mature technologies.

End users of De Dietrich glass-lined equipment are as a result in the position to make drastic modifications to their approach without having new gear to do so

De Dietrich CTJ sequence are clamped or flanged-top reactors designed which has a removable leading head for now’s cleanability needs. They have sturdier flanges and so are fabricated from thicker steel than competitive vessels, which lessens flange warpage and gives greater corrosion allowance. You will discover other functions much too which make installation, Procedure and maintenance much easier.

These cements all vary a little in corrosion resistance and will be picked depending on the qualifications with the chemicals becoming used during the vessel. The cements include a two-element program that requires an exact powder to liquid ratio, right mixing, and exact glass lined reactor india Doing work time to make certain it sets effectively. It’s vital when dealing with cement to thoroughly Keep to the curing occasions and temperatures to ensure an effective repair.

If you have any concerns and/or worries, be sure to Do not hesitate to Make contact with us for further more info

Subsequently modification of utilization: An extension or rehabilitation could be concluded just after many years.

Make sure you mill at slow pace and To put it briefly bursts to stop chipping the glass throughout the periphery of the hole. Finish the drilling course of action through the use of a ball mill or conical mill. Before setting up the patch, a filler, for example furan or silicate, is injected into the weakened location (Determine 4).

Your browser isn’t supported any more. Update it to get the finest YouTube experience and our latest attributes. Learn more

Having said that, it should be taken into account that the nozzle diameter will lower by about just one inch when this machine is used.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Michelle Trachtenberg Then & Now!

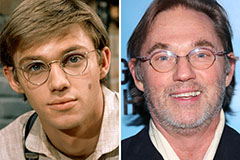

Michelle Trachtenberg Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!